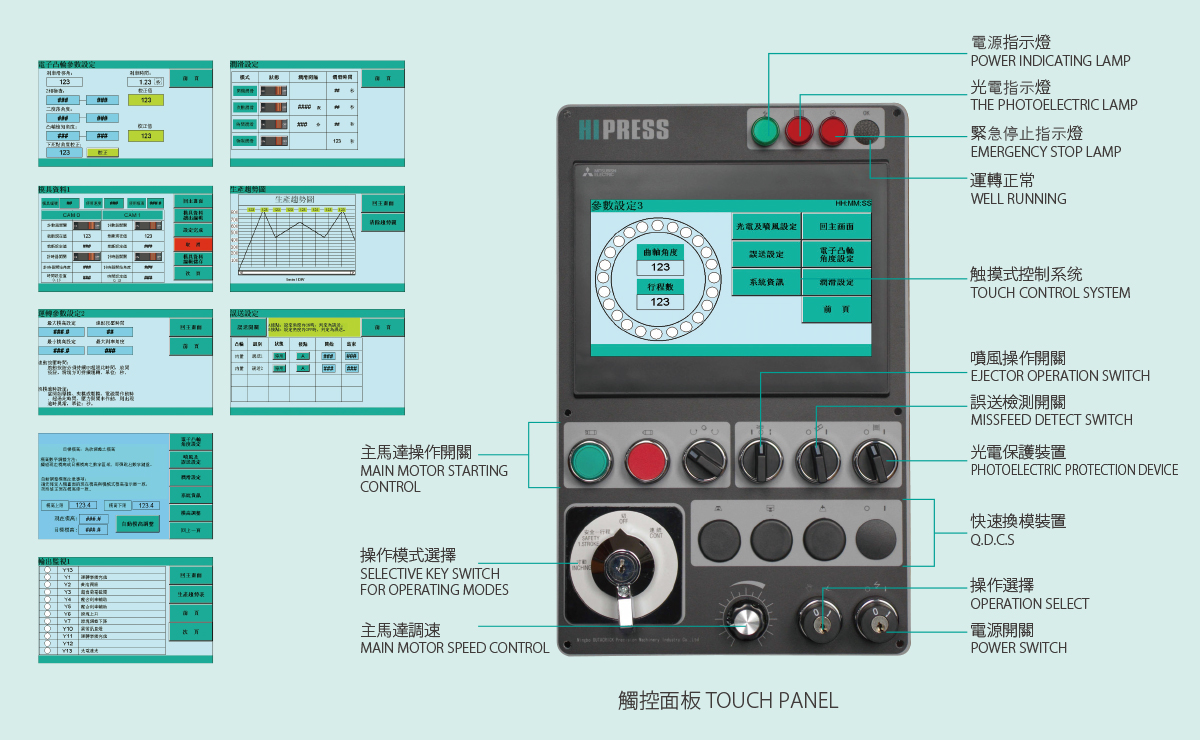

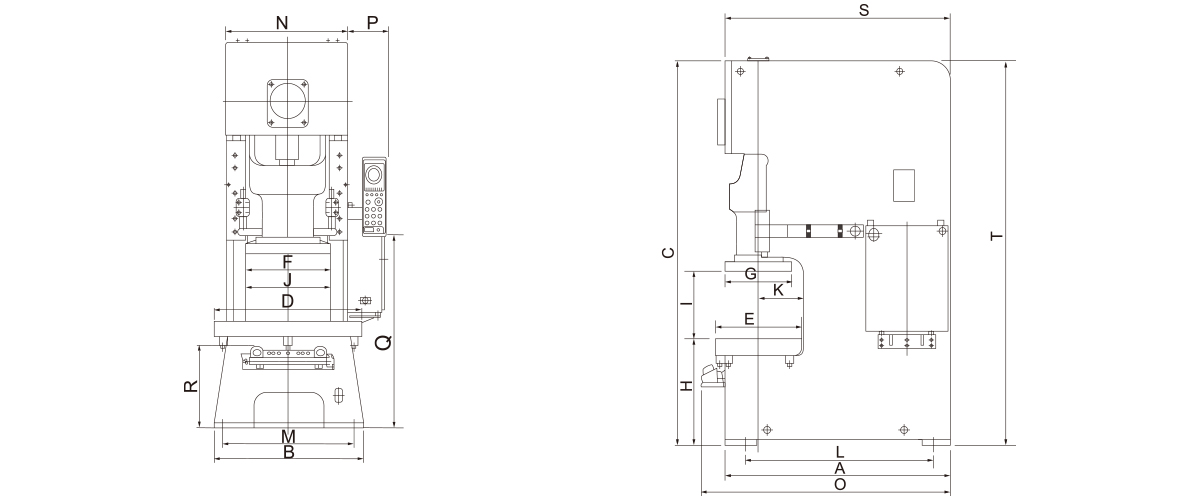

+ High rigidity

High-rigidity, high-precision frame, with welded steel board and heat treated, eliminated inner tension of press.

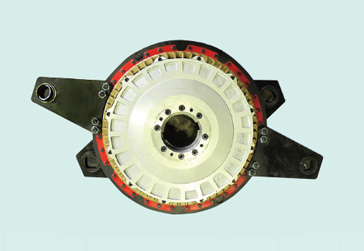

+ Balanced centre of gravity

The transmission centre is in accodance with the centre of the whole machine, ensure the accurate and stability in pressing

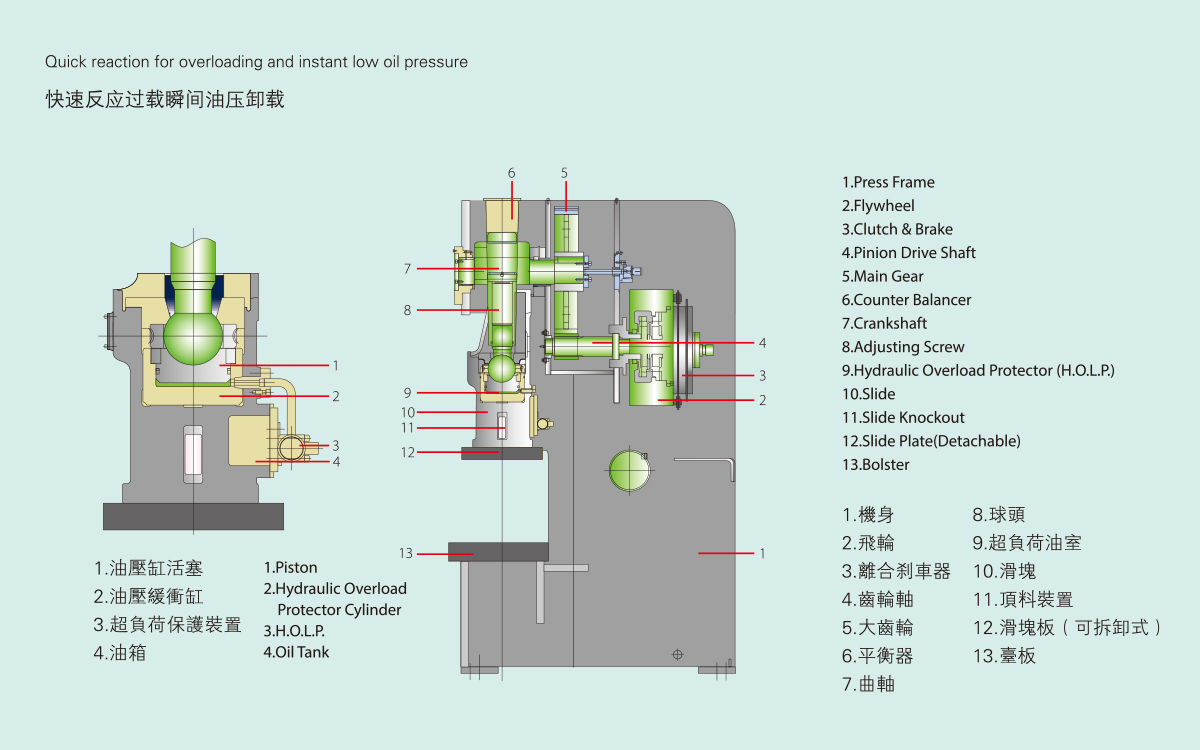

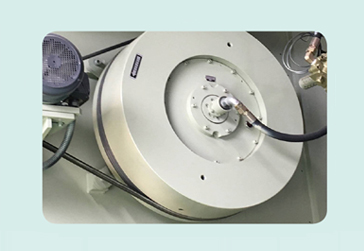

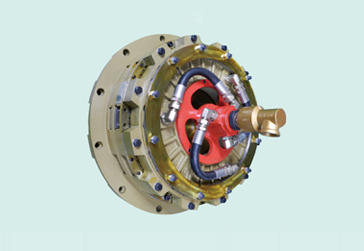

+ Safe and reliable operation

Hight-sensitive clutch/braking added international top double electromagnetic valve and overloading protection device can guarantee the accuracy and safety for sild board running and stopping.

The precision of machine adjusting is up to o.1 mm, safer and quick in production adjusting

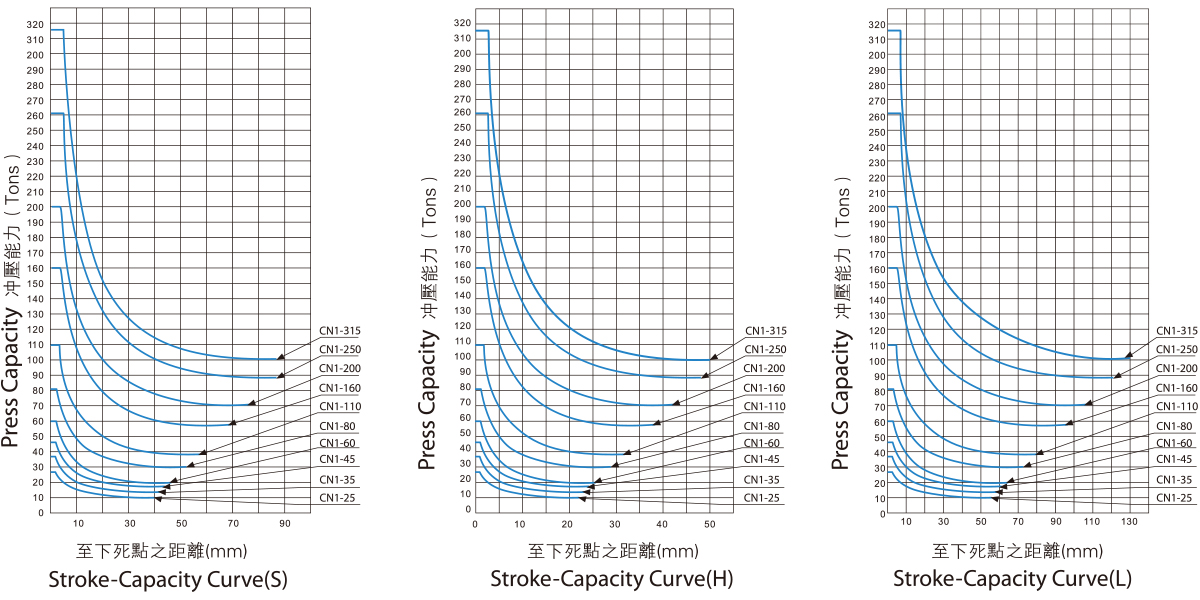

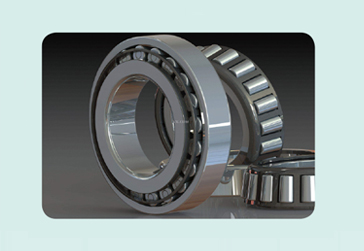

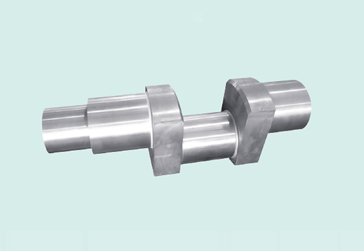

+ High-precision

The abrasive sections of crabkshaft,gear,gearshaft are treated by hardening heat treament and followed milling processing, with high abrasion resistant and balance performance, as well as stable performaces. Ensure quality and using life of punch.

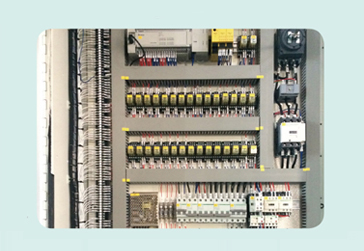

+ Automatiztion processing

Can equip all automatic feeders for automatization production, reduce the cost, promote efficiency.

+ Environment-friendly , energy-saving

Attractive appearance, low noise, low consumption, save energy,reflected the advanced design ideas by smooth and simplification appearance.