Products

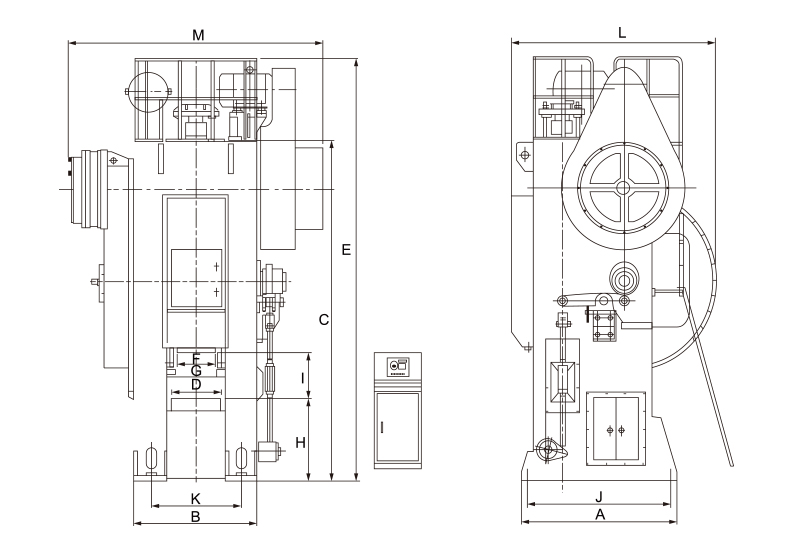

- ● CN1 series high precision compact power presses

- ● SN1 series semi-straight side high precision presses

- ● SL1 series semi-straight side high precision presses

- ● CN2 series double crank presses

- ● TNX series straight side double crank presses

- ● TH1 series close high precision high speed presses

- ● TN1 series columnar straight single crank precislon press

- ● TN2 series columnar straight double crank precision press

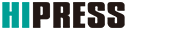

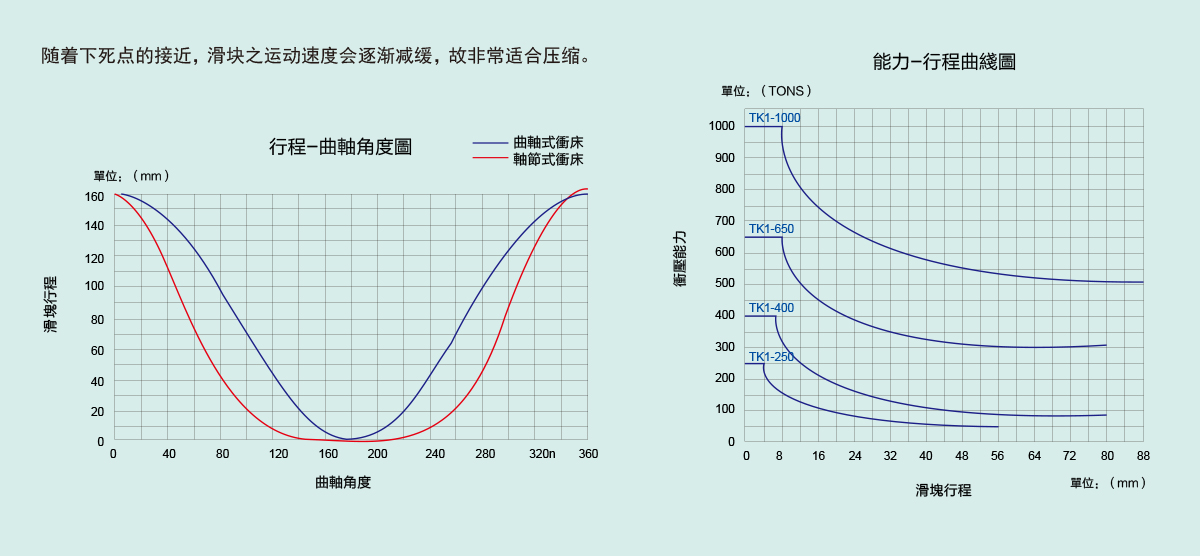

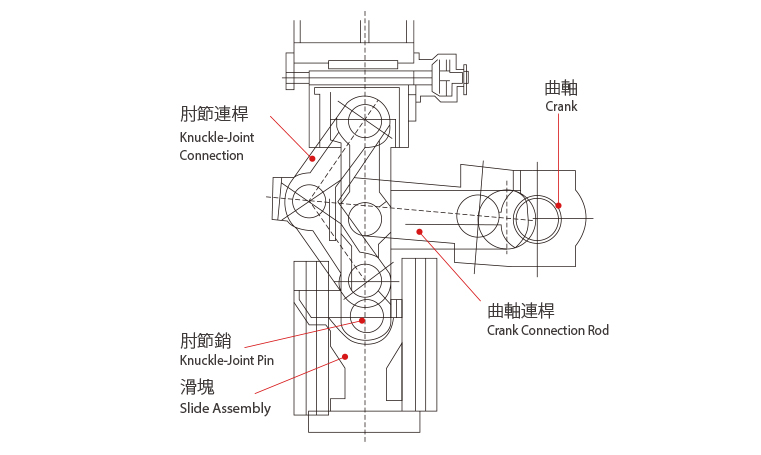

- ● TK1 series toggle type forging press

- ●Automation Peripheral Equipment

- ● CN1 series high precision compact power presses

- ● SN1 series semi-straight side high precision presses

- ● SL1 series semi-straight side high precision presses

- ● CN2 series double crank presses

- ● TNX series straight side double crank presses

- ● TH1 series close high precision high speed presses

- ● TN1 series columnar straight single crank precislon press

- ● TN2 series columnar straight double crank precision press

- ● TK1 series toggle type forging press

- ●Automation Peripheral Equipment